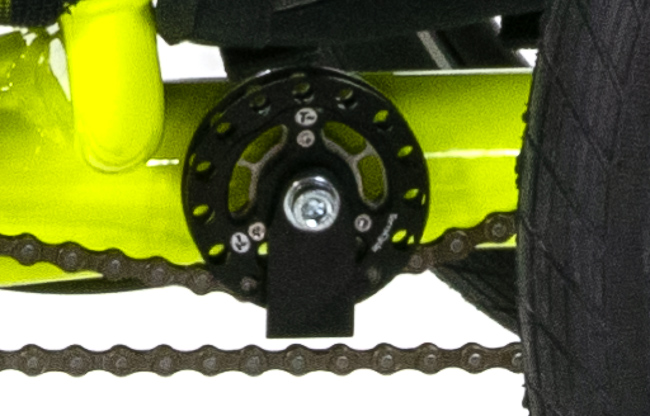

TerraCycle Elite Power Idler 15T 8mm

Availability: 4 In Stock

8mm Ceramic Hybrid Bearing

15 Tooth

What's so great about this idler?

Elite Power Side idlers have a solid metal core surrounded by a very light machined out AL frame and machined AL sideplates. Your chain is carried on a specially shaped 6AL4V Titanium cog for maximum efficiency and long life. A heavy duty aluminum bearing carrier pressed inside the cog carries a pair of high quality bearings. It's tough, light, and really sharp looking. It's the ultimate idler for almost every power side idler application.

I see it has bolts. Can I take it apart?

Yes, these idlers are designed to be disassembled if needed. They are held together with 3 stainless bolts. We don't recommend taking them apart unless they have many thousands of miles on them and you have reason to believe the bearings are finally worn out. They are precision made and there are some steps to the disassembly/reassembly that are important to follow carefully.

Since the bearings are pressed into the core, you will need a bearing press if you ever need to remove them. With any kind of reasonable care, the bearings should last tens of thousands of miles, though, and it would be rare to replace them. With a press, even a simple one, it's easy to do.

If I ever wear out the cog, can I replace that?

Yes, we can replace the cog assembly if that's ever necessary. We haven't had to do that yet, but with so many idlers out there, we're sure it will happen some day.

What about efficiency and noise?

We make exclusively toothed idlers for power side applications because they are both quieter and more efficient that way. There are a host of technical reasons for this, but the biggest and most basic one is that chains are designed to be carried by the bushings. It is a nice, big flat area designed for forces to be applied to it. Chains are not meant to be carried on the edges of their sideplates. It just doesn't work as well.

Since the core of the idler is all metal, from the chain bushings through to the bearings, there is no sponginess to soak up power. The chain sideplates aren't used to transmit power down into the idler, so there is no rubbing contact like there is on plain bedded idlers.

Noise is a complicated issue, but we expect you'll find these idlers are quieter than other idlers. The cog is specially shaped to smoothly and repeatably mesh with the chain, and unless the chain is being pulled sideways quite a bit, there will be very little rubbing. We always recommend allowing your power side idler to float side to side with the chain as it shifts.

Another common source of noise in drivetrains is insufficient contact on the idler. If there is not enough deflection of the chain at the idler, the chain and the idler don't have a chance to mesh properly. This is true for all types of idlers. You'd think that a chain only lightly touching an idler would be quieter, but because of the complex geometries involved, there is a minimum amount of bend or wrap required to get maximum silence. The amount varies with the diameter of the idler, the larger the idler, the smaller the angle required.

What bearings can you get with these idlers?

We make these idlers with 8mm Hybrid Ceramic bearings (ceramic balls, stainless steel races), 10mm, 12mm, and 3/8" ABEC rated steel bearings. We can make them with 5/8" bearings also, but that is for a special version for some Rans idler kits

What's the difference between these idlers and the Sport Series idlers?

The Elite Series idlers have titanium cogs, hybrid ceramic bearings, and completely CNC machined frames. The cog and frame are extensively hollowed out for lightness. They are designed to look as good as they work.

The Sport Series idlers have 7075 Aluminum cogs, top quality steel bearings, and injection molded fiberglass reinforced Nylon frames. They are designed to be simple, high performance, and tough. The look is much simpler, more businesslike than bling